CERAMIC FIBER BLANKET

Among all the insulating blankets, ceramic fiber blanket is one of the high temp ...

Read More >

Among all the insulating blankets, ceramic fiber blanket is one of the high temp ...

Read More >

Due to high velocity gas atmosphere in the furnace vacuum formed ceramic fiber b ...

Read More >

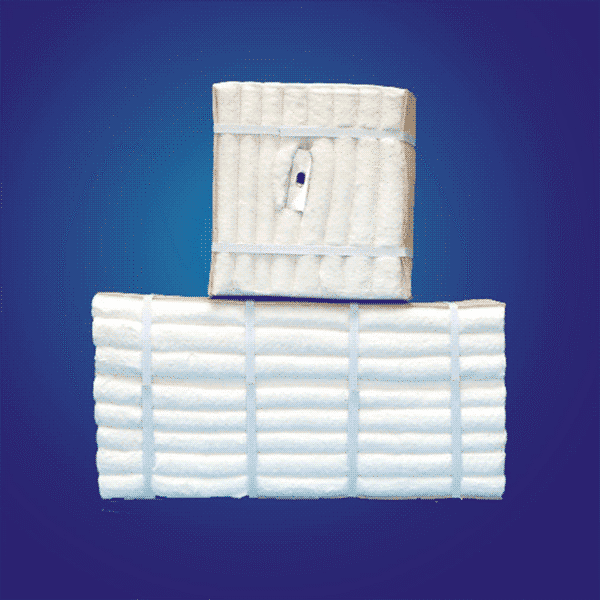

Ceramic fiber module is either stacked or folded from ceramic fiber blanket to h ...

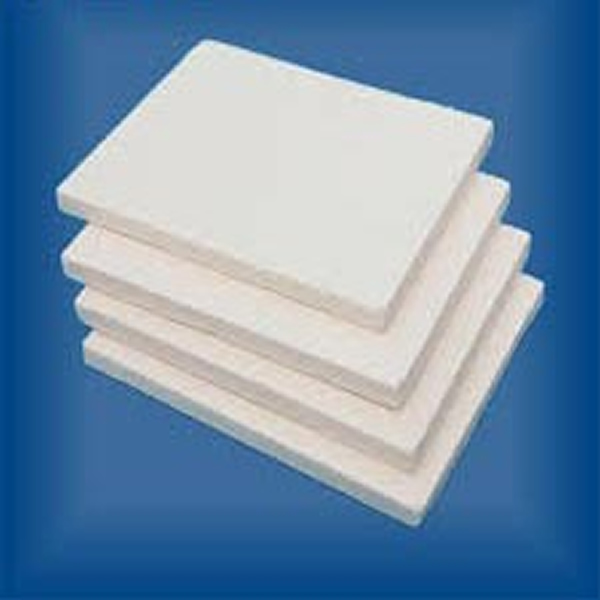

Read More >Ceramic fibreboard is aluminum silicate fibreboard, a kind of refractory materials produced by the board.Even after heating to maintain good mechanical strength, the product is more rigid than fiber blankets, blankets and support strength fiber insulation products.Ceramic fiber is widely used: cement and other building materials industry kiln lining insulation;Furnace lining insulation in petrochemical, metallurgical, ceramic and glass industries;Heat treatment furnace lining insulation;Non-ferrous metal industry backing insulation;High temperature reaction, heating equipment back lining heat preservation and insulation these industries can be used ceramic fiberboard, so the question is how to install ceramic fiberboard?

1. Clean the floating ash, oil and other debris and empty drum parts left on the concrete wall.

2. Remove the concrete blocks, inclusions and empty drums of the split roof, and repair them again.

Refractory ceramic fibreboard

3. It is required to paste ceramic fiber board with surface roughness deviation of not more than 4mm, polish the protruding concrete surface and make up the concave part when the deviation is out of tolerance (use 1:2.5 cement mortar plastering when the thickness is more than 6mm, and use polymer-bonded mortar when the thickness is less than 6mm to make up);To ensure the flatness of the whole wall is within 4mm, the square Angle of Yin and Yang, smooth up and down.

4, the construction of mortar is divided into binding mortar and surface temperature with adhesive.

5. Weight ratio of mixed binding mortar is water: mortar =1:5, mixing while adding water;The stirring time should not be less than 5min. The stirring must be sufficient, uniform, with moderate consistency and constant viscosity.

6. After the mortar is modulated, it shall be set for 5 minutes, and then stirred again before use. The mixed mortar shall be used up within 1 hour.

In addition to the excellent properties of the corresponding loose ceramic fiber cotton, the ceramic fiber board has excellent hardness, toughness and strength, and excellent wind erosion resistance.Heating does not expand, light weight, convenient construction, can be arbitrary shear bending, kilns, pipes and other insulation equipment is the ideal energy-saving materials.